PERFUSORIUS Insulating ignis Bricks

Leve Insulating Ignis Bricks factae sunt ex argilla et alumina refractoriae puritatis altae, cum congrua copia fillers organici adiectis. Hae impletores organici in processu productionis exusti sunt, inde in structuram pororum aequabili. Pro diversis ratings temperaturas, summa alumina addita cum censitione auget.

Lateres ignis leves insulating leves sunt et capacitatem repono humilis caloris habent. Habent etiam poros altos et uniformes, praestantes velit. Aptae sunt temperaturae ab CM°C ad 1550°C.

Ad signa ASTM conformans, series AB alumina sphaerarum concavarum et alumina pulveris cum ligante composito utetur, qui vibratus est et accensus ad altas temperaturas. Lateres ignis leves insulantes offerunt excellentem temperaturae observantiam et tuto adhiberi possunt in temperaturis usque ad 1550°C.

Product Features

Minimum conductivity scelerisque et velit praeclaras fornaces parietum tenuiorum permittit.

Minimum calor capacitatem, leve pondus, et humilis scelerisque conductivity patitur pro minimo calore repositione intra lateres, signanter minuendo industriam consummationem in fornacibus intermittas operatis.

Dimensiones exquisitas et altas machining accurate curare consistent articulis latericiis.

Proprietates physicae et chemica

| Classification | YK23 | YK23 | YK26 | YK28 | YK30 | YK32 | AB96 | AB98 |

| Classification temperatus (°C) | 1260 | 1260 | 1400 | 1500 | 1550 | 1600 | 1650 | 1700 |

| Densitas (kg/m³) | 550 | 800 | 800 | 900 | 1000 | 1100 | 1350 | 1500 |

| DECREMENTUM Reburning (%) JIS R2613 (°C×8h) | 0.3 1260) | 0.4 1260) | 0.4 1400) | 0.6 (1500) | 0.6 (1550) | 0.6 1600) | 0.4 1650) | 0.3 (1700) |

| Compressive vires (MPa) | 1.1 | 1.8 | 1.9 | 2.5 | 2.8 | 3 | 8.5 | 9.5 |

| Robur flexilis (MPa) | 0.8 | 1.2 | 1.2 | 1.4 | 1.6 | 1.8 | - | - |

| Scelerisque conductivity 350°C (W/m·K) | 0.15 | 0.26 | 0.26 | 0.33 | 0.38 | 0.43 | - | - |

| Scelerisque dilatatio (%) (JIS R2617, °C) | ≤0.46 | ≤0.46 | ≤0.47 | ≤0.48 | ≤0.48 | ≤0.49 | - | - |

| Chemical compositioneAl₂O₃ (%) | 40% | 40% | 54% | 62% | 74% | 80% | 96% | 98% |

| Chemical compositionFe₂O₃ (%) | 1.20% | 1.20% | 0.90% | 0.80% | 0.70% | 0.50% | 0.40% | 0.40% |

| Matching putty | RM-1400 | RM-1400 | RM-1400 | RM-1600 | RM-1600 | RM-1750 | RM-1750 | RM-1750 |

Chemical composition

| Classification | B4 | B5 | B6 | B7 | C1 | C2 |

| Classification temperatus (°C) | 1200 | 1300 | 1400 | 1500 | 1300 | 1400 |

| Densitas (kg/m³) | 780 | 780 | 890 | 960 | 1060 | 1140 |

| DECREMENTUM Reburning (%) JIS R2613 (°C×8h) | 0.3 (1200) | 0.3 (1300) | 0.6 (1400) | 0.9 (1500) | 0.7 (1300) | 0.8 (1400) |

| Fortitudo compressiva (ASTM C93, Mpa) | 1.4 | 1.5 | 2.4 | 3.5 | 3.6 | 4 |

| Robur flexilis (ASTMC93, Mpa) | 0.8 | 0.8 | 1.5 | 2 | 2.1 | 2.6 |

| Scelerisque dilatatio (%) (JIS R2617, C) | 0.5 | 0.5 | 0.48 | 0.5 | 0.5 | 0.5 |

| Al₂O₃ (%) | 41% | 41% | 41% | 62% | 40% | 41% |

| Fe₂O₃ (%) | 1.20% | 1.20% | 1.40% | 0.90% | 1.20% | 1.20% |

| Matching putty | RM-1400 | RM-1400 | RM-1400 | RM-1400 | RM-1400 | RM-1400 |

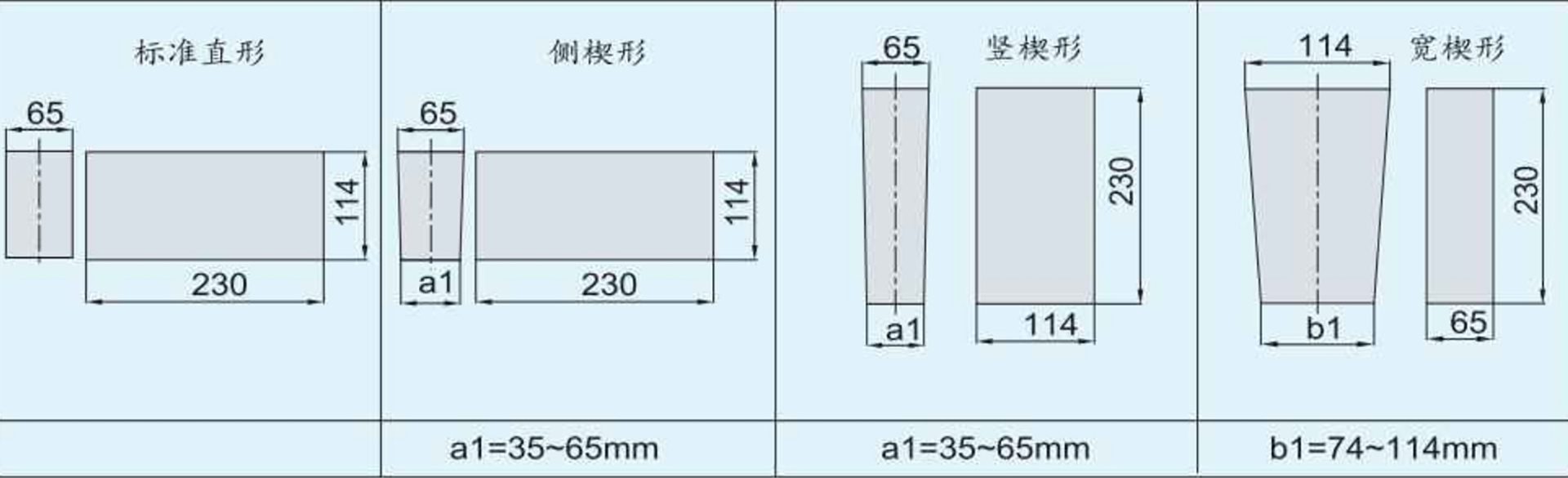

Dimensiones

-

Introductio to Vacuum Caloris Curatio Curatio caloris vacuum est processus metallurgici provectae ad emendandas proprietates mechanicas et durabilitatem industrialium componentium. Materias calefaciendo in ambitu vacuo, oxidatio et contagione elevat, inde in certa et constanti materiali effectu. Haec ars late applicatur in industriis sicut aerospace, autocinetum, instrumentum fabricandi, et electronica. Consectetur Material virtus et duritia Una ex primis commodis vacui cal...